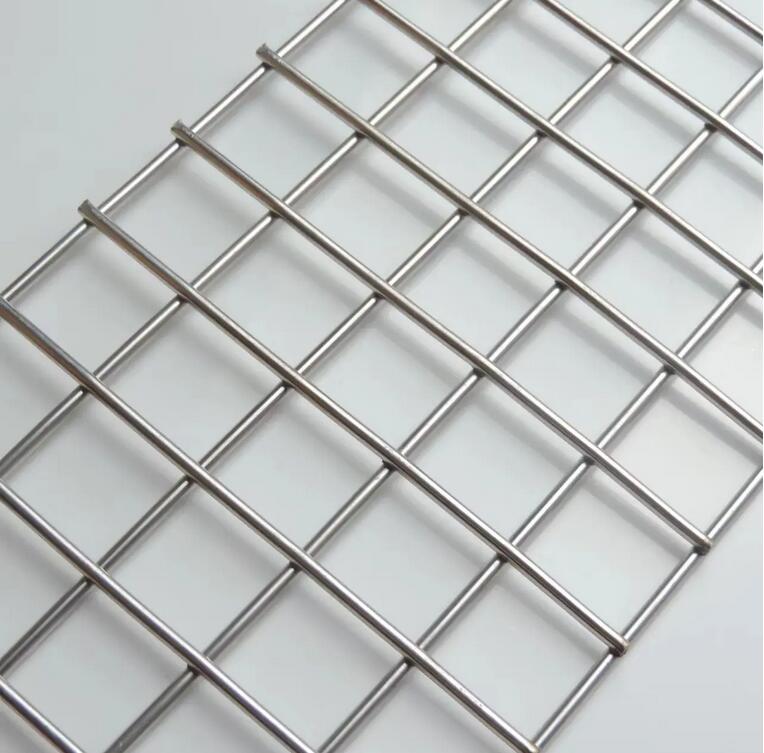

Stainless steel mesh is a popular material used for a wide range of applications, from industrial filtration to decorative purposes. The most commonly used types of stainless steel mesh are 304 and 316, both of which have unique properties and characteristics that make them suitable for different applications. In this article, we will discuss the differences between 304 and 316 stainless steel mesh and their respective uses.

What is stainless steel mesh?

Stainless steel mesh is a type of wire mesh made from stainless steel wire. It is commonly used in applications that require strength, durability, and corrosion resistance. Stainless steel mesh is used in a variety of applications such as filtration, sieving, and fencing. It can be made from different grades of stainless steel, with the most common being 304 and 316.

What is 304 stainless steel mesh?

304 stainless steel is a type of austenitic stainless steel that contains 18% chromium and 8% nickel. It is the most commonly used stainless steel and is known for its excellent corrosion resistance, high strength, and good formability. 304 stainless steel mesh is used in a wide range of applications, including food processing, pharmaceuticals, and architecture. It is also commonly used for sieving and filtering in the mining and chemical industries.

What is 316 stainless steel mesh?

316 stainless steel is a type of austenitic stainless steel that contains 16% chromium, 10% nickel, and 2% molybdenum. It is known for its excellent corrosion resistance, particularly in environments that are exposed to chlorides, such as marine environments. 316 stainless steel mesh is commonly used in applications that require high corrosion resistance, such as marine and pharmaceutical applications, as well as in the food and beverage industry.

Differences between 304 and 316 stainless steel mesh

The main difference between 304 and 316 stainless steel mesh is their corrosion resistance. While both grades are corrosion-resistant, 316 stainless steel mesh is more resistant to corrosion than 304 stainless steel mesh, particularly in environments that are exposed to chlorides. This makes 316 stainless steel mesh ideal for marine applications or applications that require exposure to harsh chemicals.

Another difference between the two grades is their strength. 316 stainless steel mesh is generally stronger than 304 stainless steel mesh, particularly in high-temperature environments. This makes 316 stainless steel mesh suitable for applications that require high strength and durability.

In terms of cost, 316 stainless steel mesh is generally more expensive than 304 stainless steel mesh. However, the added cost is often justified by the superior corrosion resistance and strength of 316 stainless steel mesh, particularly in applications that require it.

In conclusion, the main difference between 304 and 316 stainless steel mesh is their corrosion resistance and strength. 316 stainless steel mesh is more resistant to corrosion and generally stronger than 304 stainless steel mesh. While 316 stainless steel mesh is more expensive, the added cost is often justified by its superior properties, particularly in applications that require it. It is important to consider the specific requirements of your application when choosing between 304 and 316 stainless steel mesh.

The above is the introduction of the “What is the difference between 304 and 316 stainless steel mesh” article, if you have any questions, please leave a message to consult us!

Request a quote

We will assist you 24/7